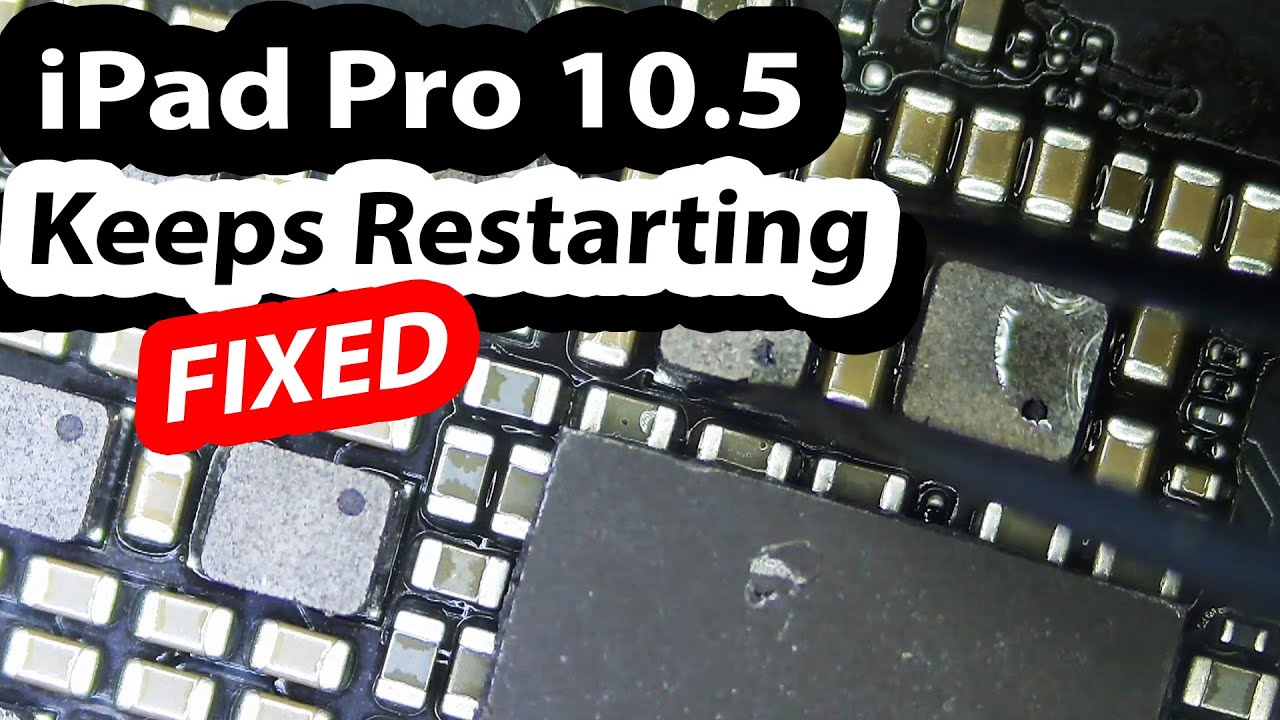

iPad pro 10.5 keeps rebooting after a drop. What is causing the problem? By NorthridgeFix

In this video we're going to be working on an iPad Pro 10.5 inch, I'm just reading what the customer mentioned in the ticket description here. If we quickly read what the customer mentioned here, one day, my daughter's iPad kept rebooting every few minutes, so we thought it was a software issue. So we did the software upgrade that did not help it made it worse. It stays in the rebooting screen. The screen was cracked, and it looks like the customer did change the screen, but that did not change the outcome. The iPad continues to just show the rebooting screen.

So now, what can we tell from what we just read? We can tell that the tablet suffered a drop screen broke customer did a software update or restore that did not solve the rebooting issue and customer changed the actual screen, which is the right thing to do to see if that will solve the problem, but that did not solve the issue. The first thing I want to do is quick physical inspection on the board to see, if there's anything obvious, since this tablet did suffer a drop, we want to look for, possibly maybe loose components, broken coil. I've seen this happen with coils and right there. That's exactly what I was looking for. We have a broken call here, and I've seen this more than once, where the coil is either loose or it's broken off the board.

We still see the edges of the component here: it's not the soldering that broke it's the actual component, that's most likely the problem. I do have a donor board here. This is an iPad Pro 10.5 donor board that we have and uh we're gonna, be using the coil from this board and put it on the customers board. The first thing I want to do is disaster those broken pieces and, let's also remove this- we're gonna, add a little of solder on the pads here. That's enough and that's enough.

What I want to do now is grab that component from the donor board. I have the donor board right here. Let's use hot air and let's solder, that component on the customer's board over here: okay, that's it all we have to do is assemble and test. I'm going to give it two big buzz to reassemble, and I'll, be back. That's the component that we soldered right here, and we'll see.

Okay, so big boss, reassembled the board, and he said it's a no-go. The tablet is still rebooting. I'm going to take another look at the board just to see if there's anything else that we may have missed start from the very top here. I should have done this from the beginning. Where I inspected every part of the board.

I quickly saw that we had a missing coil, I replaced it and gave it back to him right now. I want to continue with physical inspection just like. If you are driving an old vehicle, 1950s 1960s 1970s, you hit a wall you're going to go flying out of the window. The body is strong, the connection between you and the seat is weak. So upon hitting the wall, you're going to fly out of the window same thing here, the actual legs, the pad and solder, is very strong, but the component itself, the coil itself, the connection between the call and the legs is not so strong.

So upon impact you can lose a coil or the call may get loose, or it may get broken right now. We did not see the call inside the tablet, but that's probably because the customer replaced the screen and that coil most likely fell out without the customer noticing it's a tiny component, so I'm doing more physical inspection on the board just to see if we have anything else missing, so far everything looks clean. I want to check on those calls I'm going to tap every coil just to make sure we do not have anything loose. That's the one that we changed. Oh, look at that look at that here.

We have a missing call here too. Unbelievable. Look at this. We do see the actual leg still stuck on the pads, but the coil is gone. Let's continue and there's one here too, what okay, let's look and see where the other one was right here: wow three missing coils on one board that shows how important physical inspection is.

Okay, I'm not going to be able to fit my tweezers on this area of the board. So let's use our regular tweezers. Let's start by prepping the pads, just a tiny bit now we're going to grab the coil from the donor board. Let me just make sure that we are grabbing the right coil. So it's to the right of that chip and right there, that's the one! So, okay! So that's one and let's do the other one.

It's the one in the middle and let's solder that onto the customers board, I'm going to give it to big boss to try again and see if the tablet still restarts I'll be back. Okay, so the screen is assembled. I did not turn it on, yet I still have the battery separated from the motherboard, so we need to remove the separator and I need to press on the battery connector and let's turn it on. Okay and tablet is on usually within two seconds three seconds. It turns off and restarts looks like it's gonna work, no rebooting great great great.

I never got to the screen before it's always Apple logo. One two seconds off Apple logo, one two seconds off right: now it booted up to the operating system and great awesome job is done. I hope you enjoyed the video don't forget to like and subscribe leave a comment. If you have any questions, and we'll do something else in the next video you.

Source : NorthridgeFix